We're Here to Help, Every Step of the Way

From installation to on-going support, we are dedicated to ensuring the efficiency and accuracy of your torque tools at every stage. Count on our expert assistance for a reliable, seamless experience.

Installation & Support

From initial installation to on-going support, we are committed to maximizing the efficiency and accuracy of your torque tools.

Trust in our dedicated assistance for reliable experience.

Explore seamless torque tool installation with our comprehensive support services.

Our experts ensure a smooth setup, providing step-by-step guidance to optimize tool performance.

Essential safety practices

for torque tools and testers

General how to's

Additional helpful info

Detailed Drawings

To view or download a detailed drawing, refer to the documents section on the product group page. There is a drop-down menu labeled "Detailed Drawing." From this menu, find the drawing based by part number. Once selected, click the download button.

Manuals

To view or download a product manual, refer to the documents section on the product group page. There is a drop-down menu labeled "Manuals." From this menu, select the document needed. Once selected, click the download button.

3D Drawings

We are happy to provide 3D drawings for those engineers who are in the process of project development and need to ensure our tools fit. To receive a 3D drawing, email our technical support team. Please be prepared with part number, tool description, and the format you need.

Important battery info

for torque tools

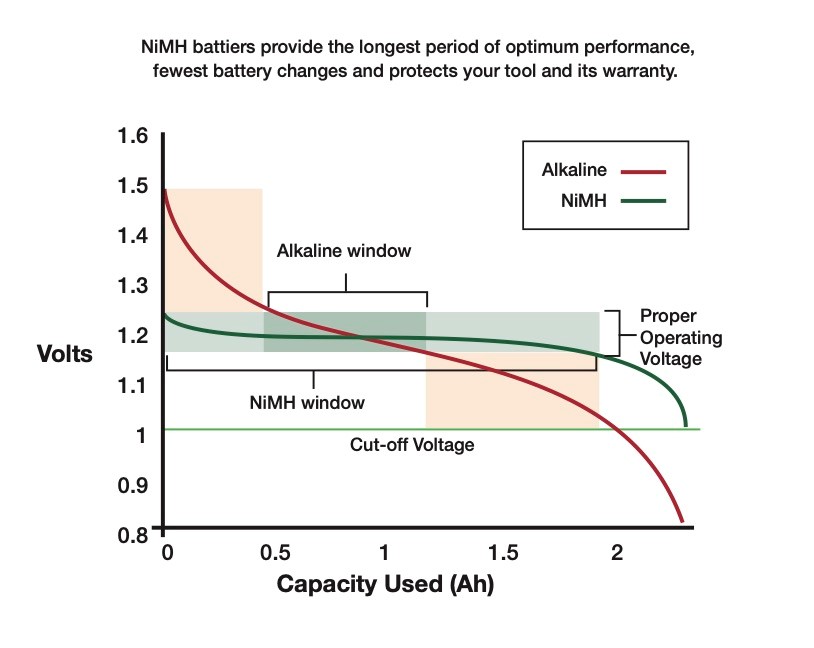

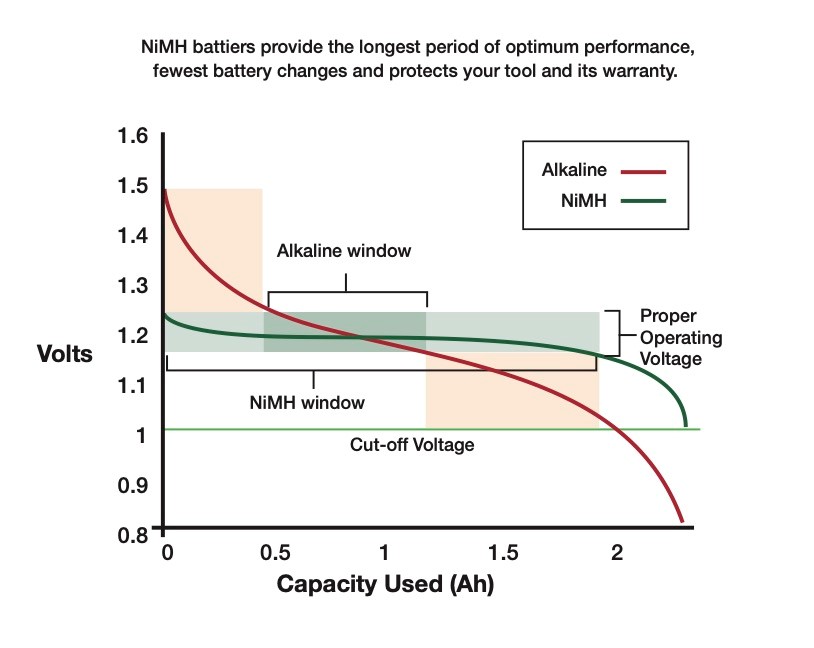

Battery Selection and Sturtevant Richmont Tools

We build highly durable tools with sophisticated electronics. We design circuits to be as energy-efficient as possible. We are also concerned about the environment. Our tool and tester circuit boards are designed on the highly consistent 1.2-volt power curve provided by rechargeable NiMH batteries. Other batteries like Alkaline or Lithium batteries provide 1.5 volts in the power curve. The additional voltage can damage the circuit board. Compare 1.2 Volts of a AAA NiMH and the 1.5 Volts of a AAA Alkaline battery. That Alkaline battery provides 25% more current to the electronics.

NiMH Battery Facts

- NiMH rechargeable batteries come in a range of mAh (milli-amp hour) ratings.

- Always use the largest mAh rated batteries available.

- The TAC wrench requires a minimum of 1,000 mAh rated battery.

- The rating difference is the number of operational hours the battery will supply.

- The higher the mAh rating, the longer the batteries last between charges.

- High mAh rated batteries take longer to charge than low mAh rated batteries.

- Quick chargers can shorten useful battery life.

- The trickle charger is the best way to recharge the batteries and preserve battery life.

Tools Using NiMH Batteries

- 1100 Series Exacta 2 Digital Torque Wrenches

- 1200 Series Exacta 2 Digital Torque Wrenches

- 1350 Series Exacta 2 Digital Torque and Angle Wrench

- TAC Digital Torque and Angle Click Wrench

- 1350 Series TD Torque Driver

- Exacta 2 Digital Torque Wrench

- System 8 Digital Torque Tester

- Torq-Tronics 2 Digital Torque Tester

When lives are at stake, engineers reach for Sturtevant Richmont tools to ensure that fasteners are torqued to specification. Whether you are using our tools in a factory, under the sea, or up in space, tool failure is not an option. Tool failure can cause fasteners to come undone and pieces to come apart. Improper use of torque tools can also cause fasteners to come undone. Those concepts have always been embedded in our brains as we design our tools. Safety first is more than a slogan or a poster on the wall. It is a way of life.

Ergonomics

Ergonomics is another important factor in tool use. We don't make some tools because of their design flaws. For example, a flex head torque wrench makes it easy for the operator to sideload the torque application by varying from 90-degree torque application. Cam-over or break-away wrenches are not ergonomically sound. Depending on the application and where the operator is using the cam-over wrench relative to his or her body, the wrench break-over can cause repetitive motion injury by forcing the wrist to rotate in a non-ergonomic manner. We build tools that eliminate the human influence on torque application. That protects the quality of the build being assembled. We also want to protect the operator. As a result, we don't make cam-over tools. It simply does not fit with our value set.

Torque Tester Safety

- Calibration weights can cause the tester and its base to tip.

- Always wear safety goggles (users and bystanders).

- Always wear eye protection.

- Tipping base can cause injury.

- Always read the instructions on torque tools and torque testers.

Torque Wrench Safety

- Over torquing can cause breakage.

- Never over torque a fastener or exceed wrench rated capacity.

- The wrench can break while creaking fasteners loose.

- Force against flex stops on flex head torque wrenches cn cause head breakge.

- An out-of-calibration torque wrench can part or cause tool breakage.

- Wear safety goggles (user and bystanders).

- Always wear eye protection.

- Do not exceed rated torque.

- Do not use a torque wrench to break fasteners loose.

- Periodic recalibration is necessary to maintain accuracy.

- Broken tools can cause injury.

- Taking interchangeable heads over their rated torque value can cause the head to break.

- Always read the instructions.

Detailed Drawings

If available, a detailed drawing is provided for individual products. To view or download a detailed drawing, refer to the documents section on the product group page. There is a drop-down menu labeled "Detailed Drawing". From this menu, find the drawing based on part number. Once selected, click the download button.

Manuals

To find a product manual, refer to the douments section on the product group page. Threre is a drop-down menu labeled "Manuals." From this menu, select the document needed. Once selected, click the download button.

3D Drawings

We are happy to provide 3D drawings for those engineers who are in process of project development and need to ensure our tools fit. To receive a 3D drawing, email our technical support at [email protected]. Please be prepared with part number, tool description, and the format you need.

The FAQ section addresses common "hands-on" questions pertaining to our products and doing business with Sturtevant Richmont. From setting the torque on various torque devices to ratchet maintenance, these quick guides will help answer some of your most common questions.

Click on each of the following:

- How do I set the torque on SR torque wrenches?

- How do I set the torque on SR micrometer adjustable torque wrenches?

- How do I set the torque on ExacTorq adjustable torque screwdrivers?

- How do I use an SR interchangeable head torque wrench on a left-hand thread?

- What is "Residual Mode" on Exacta and Exacta 2 and how does it work?

- How do I replace a slide pin ratchet on ratcheting square driver wrenches?

- Can I replace the Stancor AC to DC converter for my Torq-Tronics2?

- How do I determine the model number of a specific SR torque wrench?